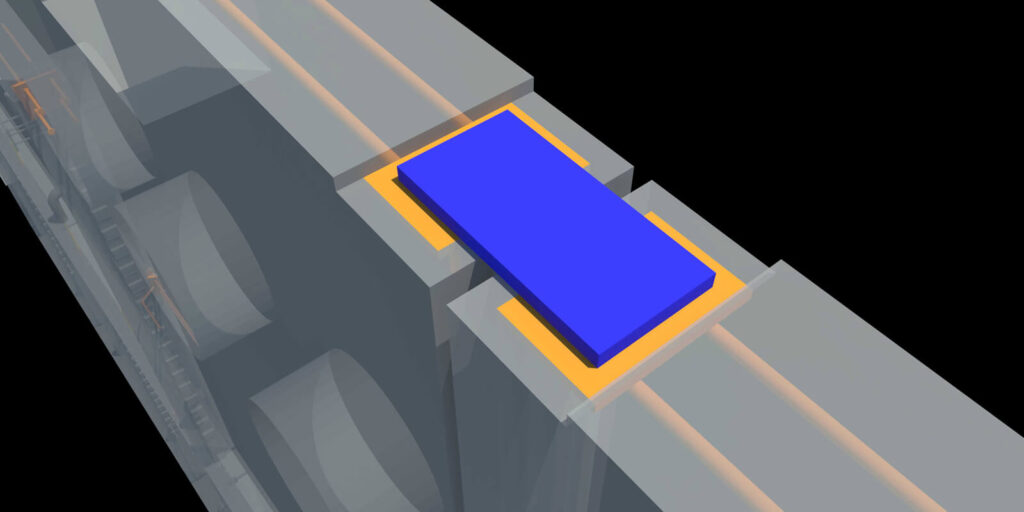

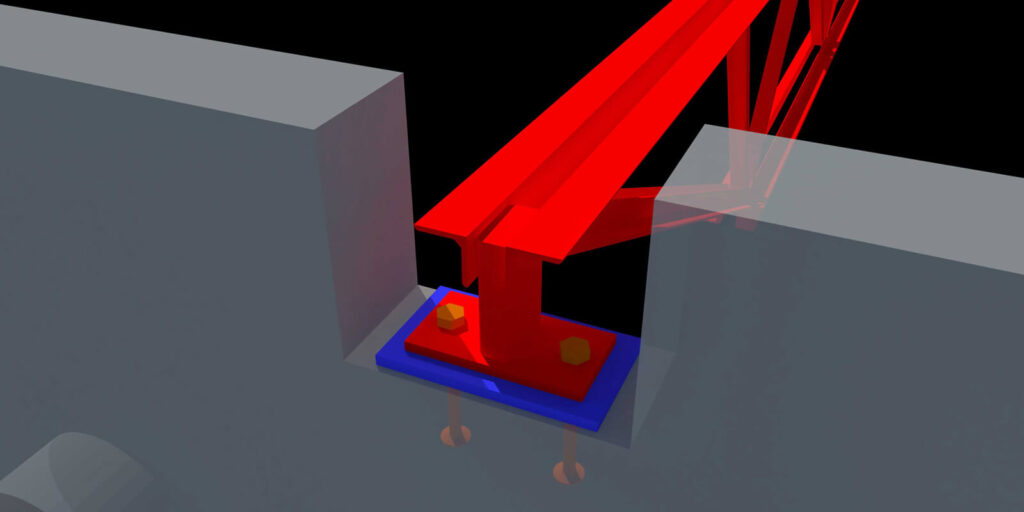

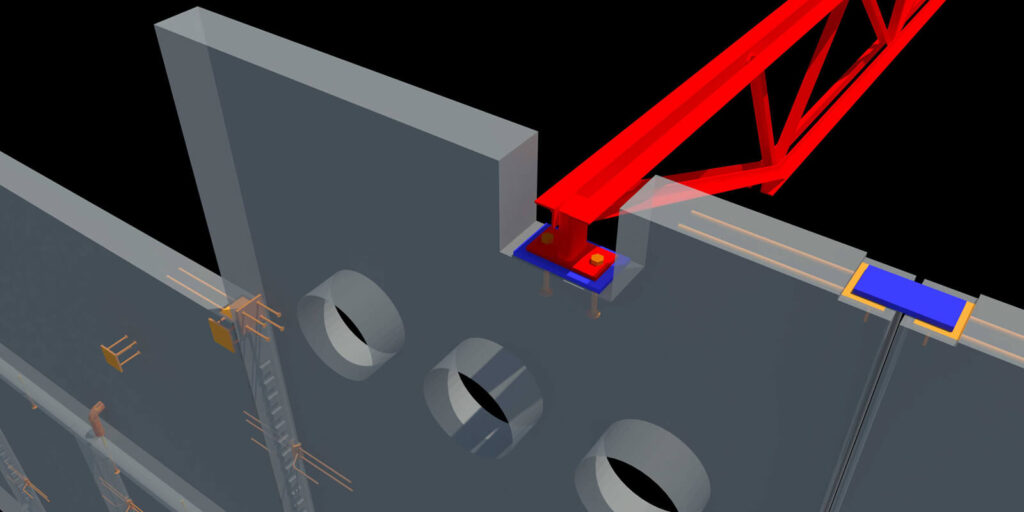

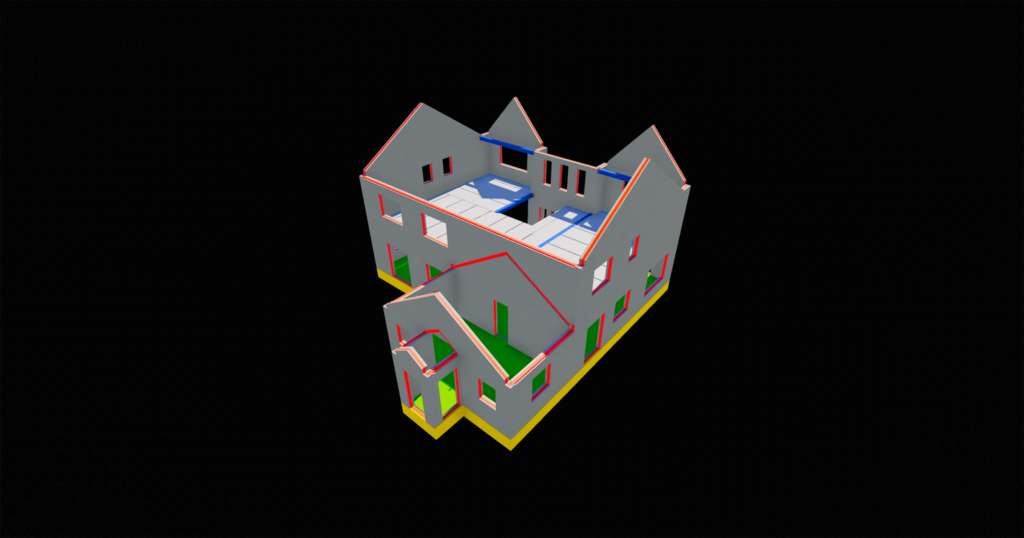

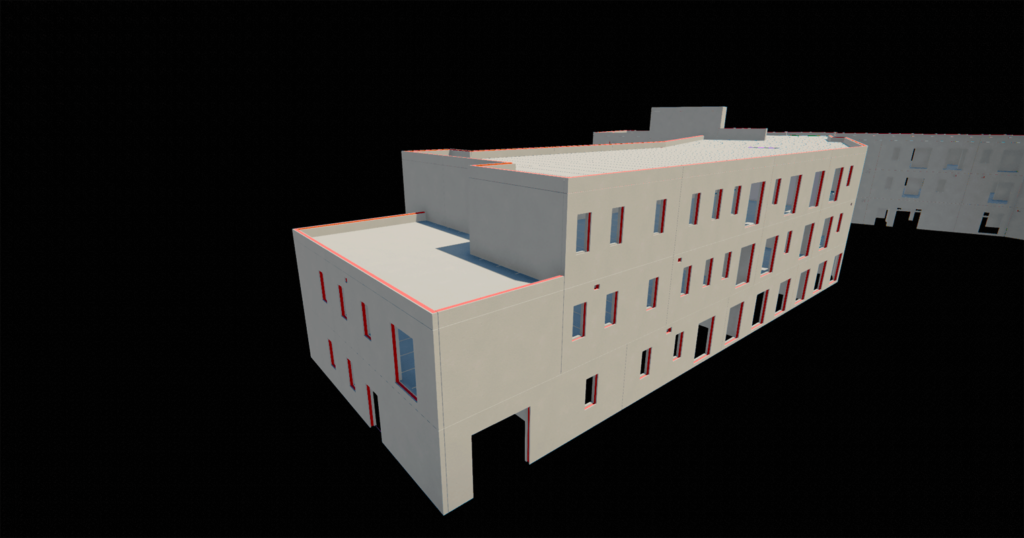

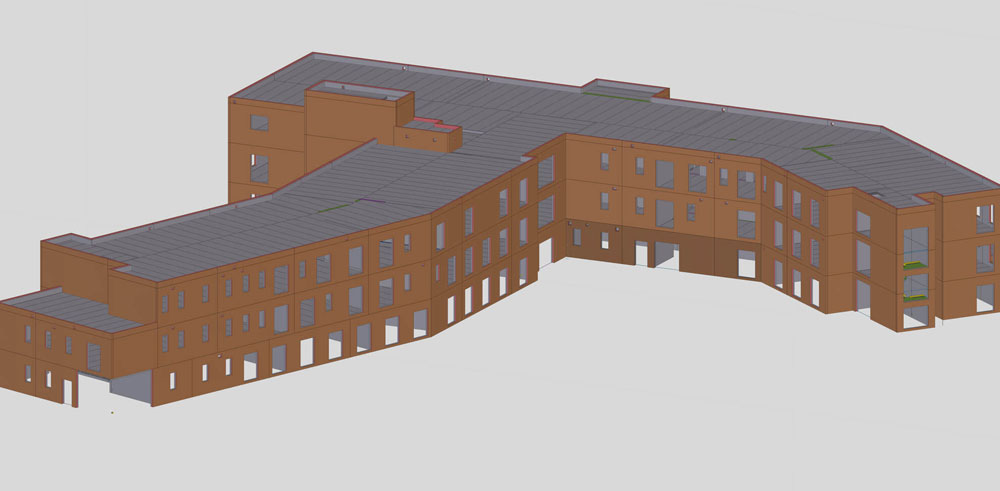

Arrow services provide Precast Detailing. The Precast panels must be carefully detailed where they connect with other components of the building. At Arrow our engineers have the expertise to provide precise detailing & shop drawings for all precast types using AutoCAD & Tekla Technologies.

Precast concrete refers to factory made casted concrete panels. Precast concrete panels have better structural performance, durability and fire resistance. Precast helps complete projects faster. The development of precasting technique opened up possibilities to architects, designers, engineers and contractors.

We have worked on the following precast projects which includes:

Software’s Used in Precast Detailing

Precast detailing is typically done using computer-aided design (CAD) software that can create 2D and 3D models of the precast elements.

AutoCAD

Widely used for 2D and 3D detailing of precast concrete.

Revit

A BIM (Building Information Modeling) software that helps create 3D models and provides a more collaborative approach to the detailing process.

Tekla Structures

A software specialized in structural detailing, including precast concrete elements, allowing for detailed modeling and integration with other disciplines.