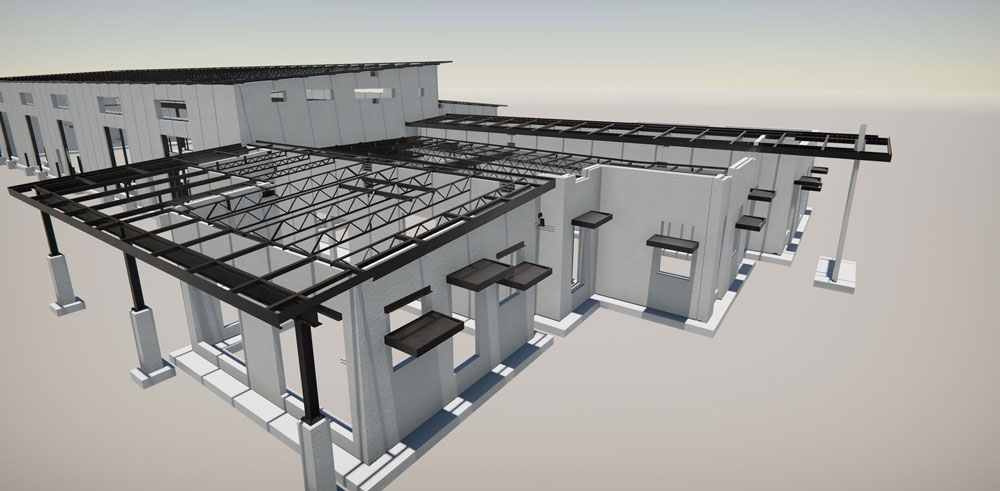

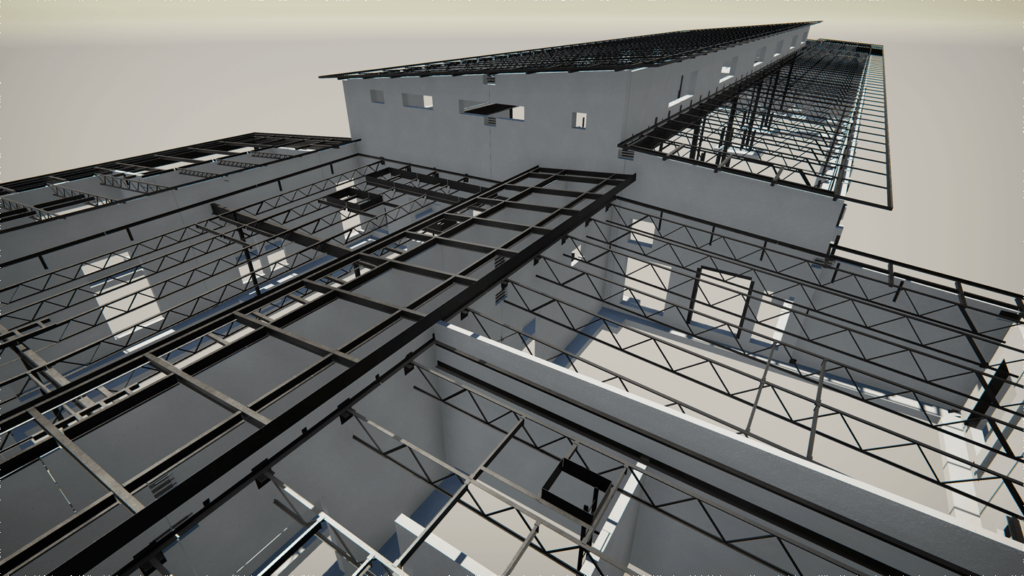

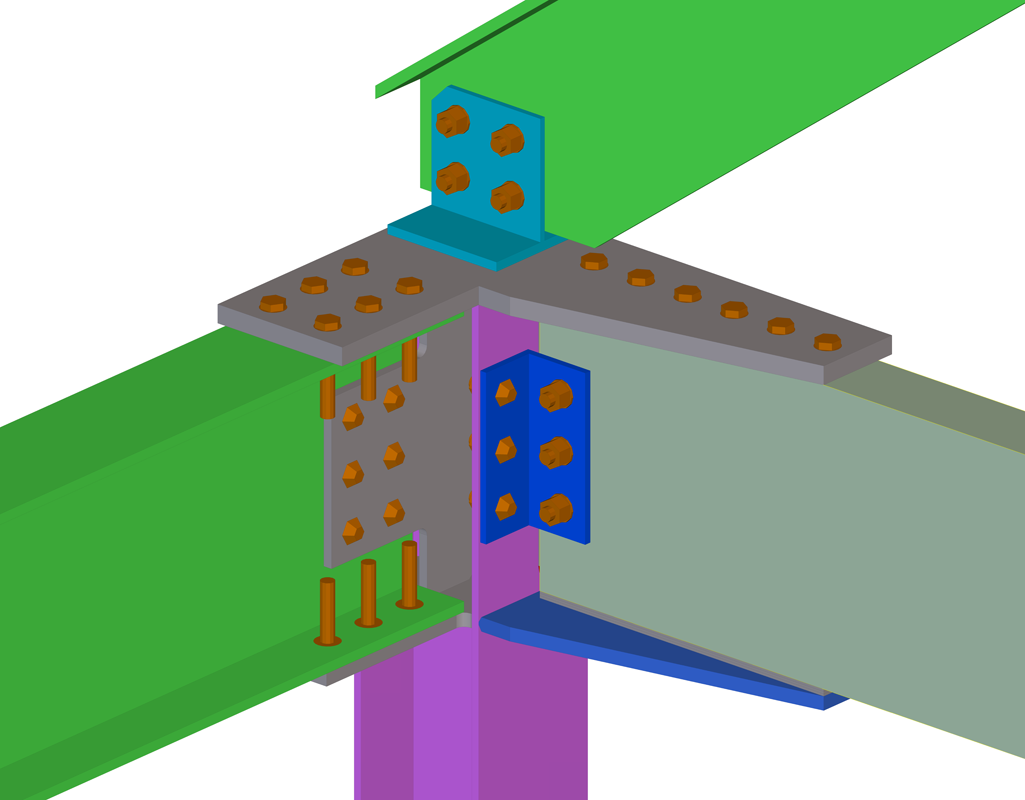

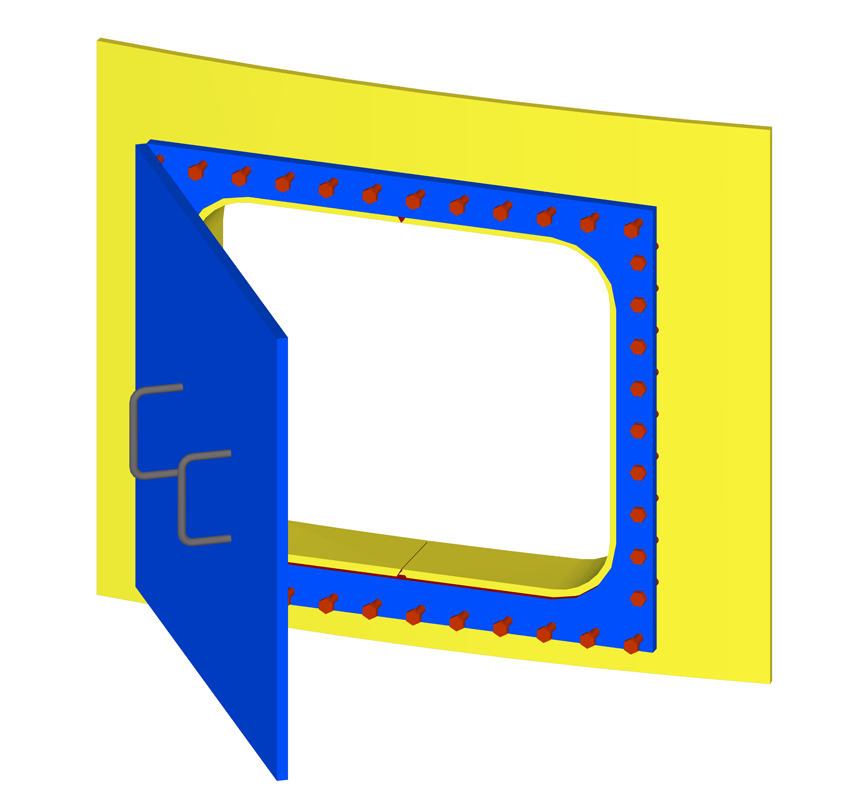

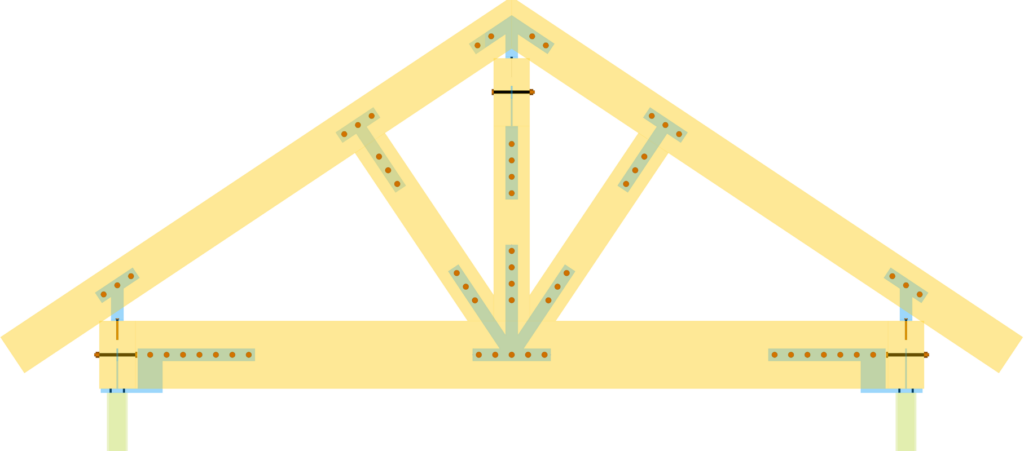

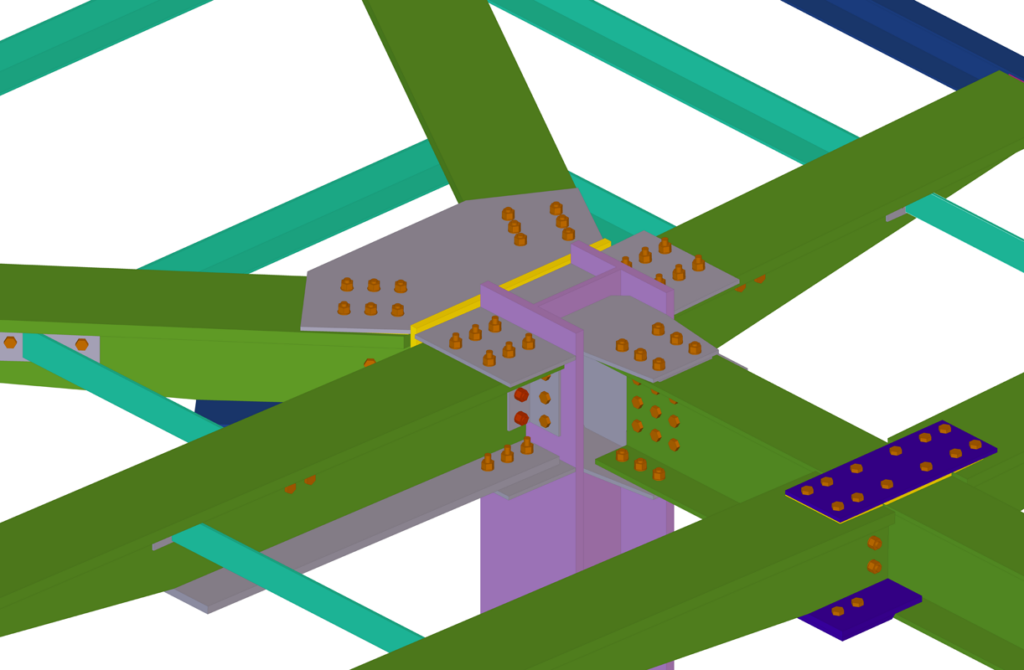

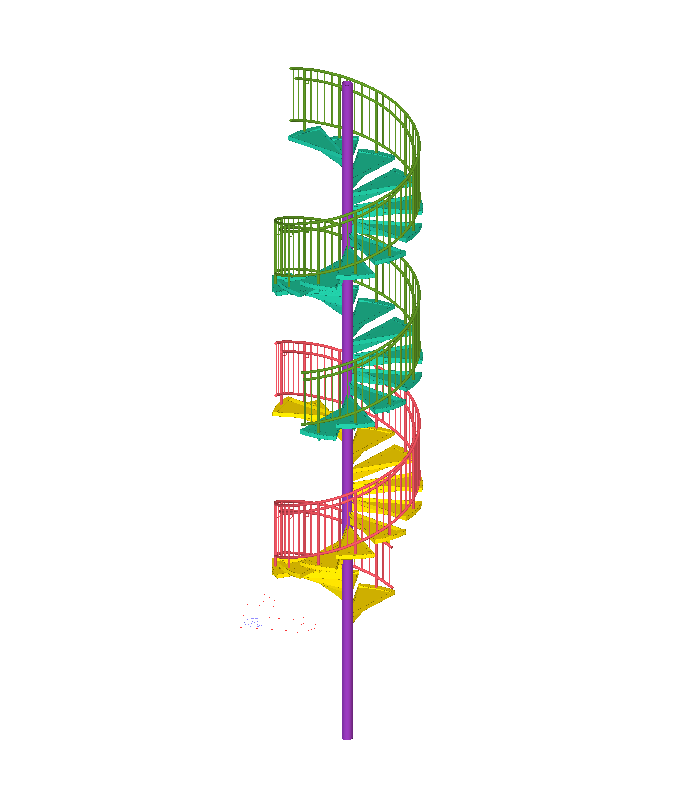

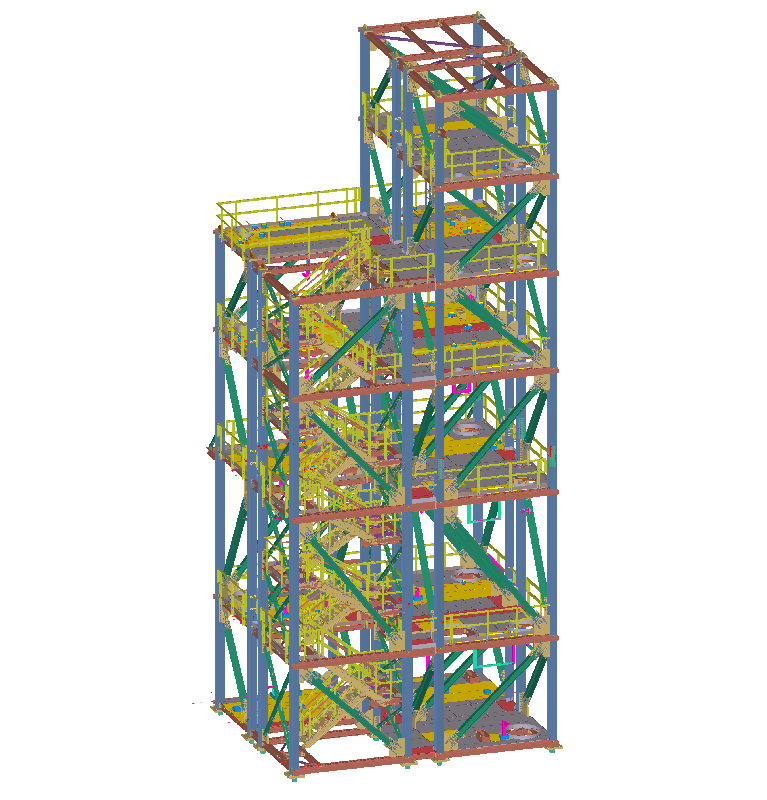

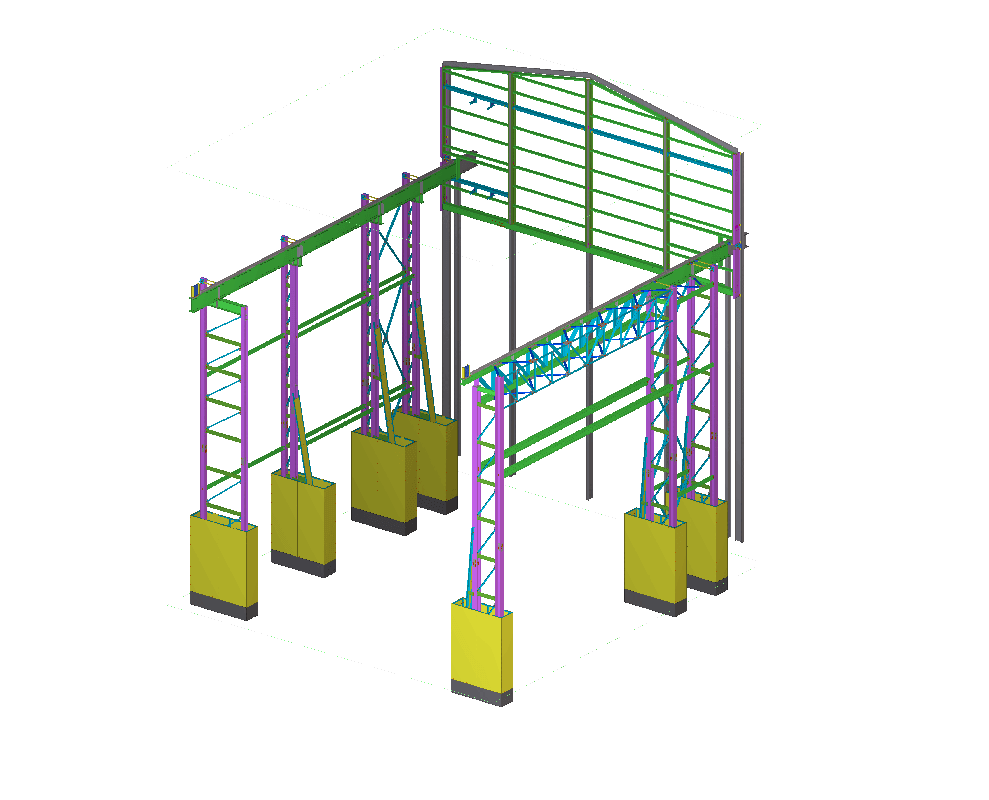

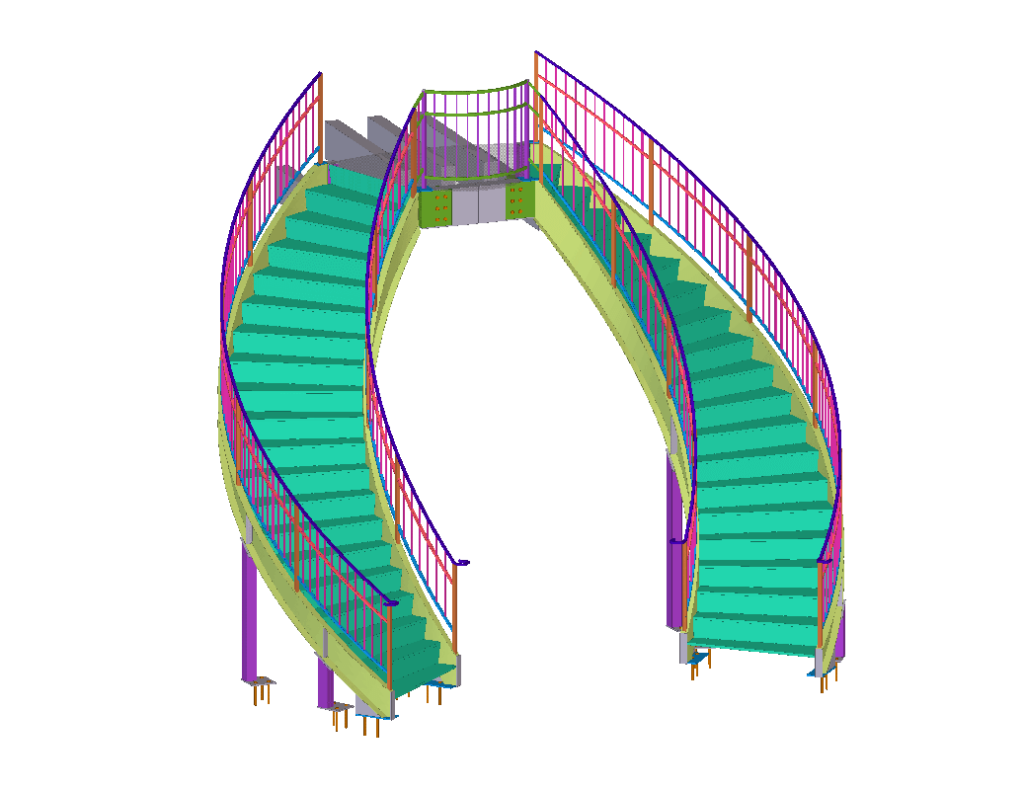

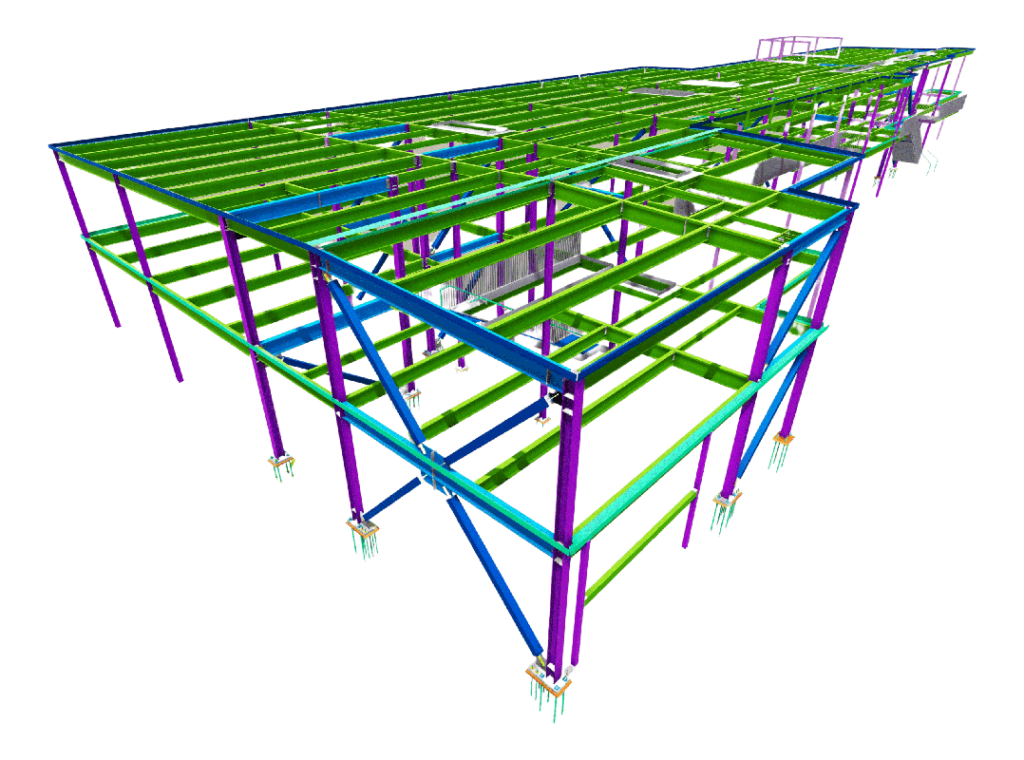

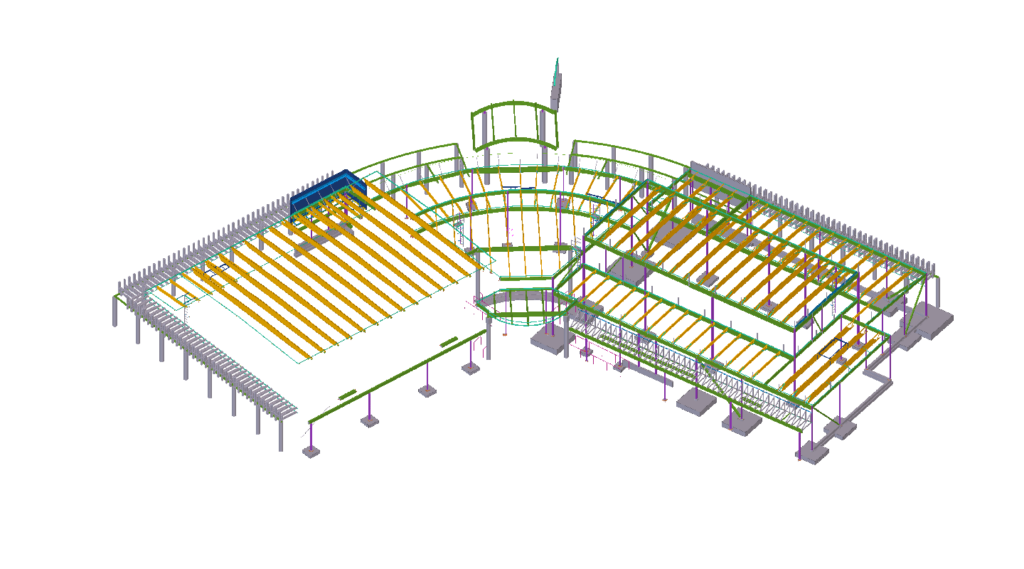

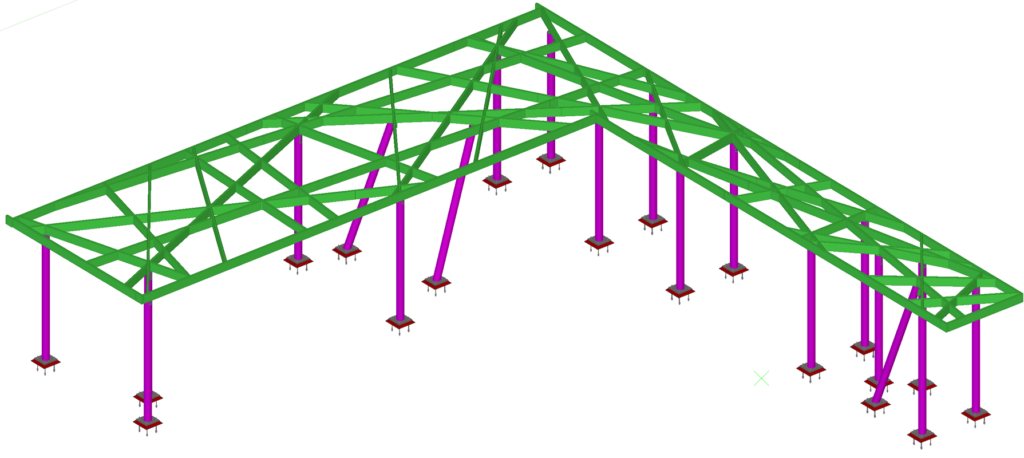

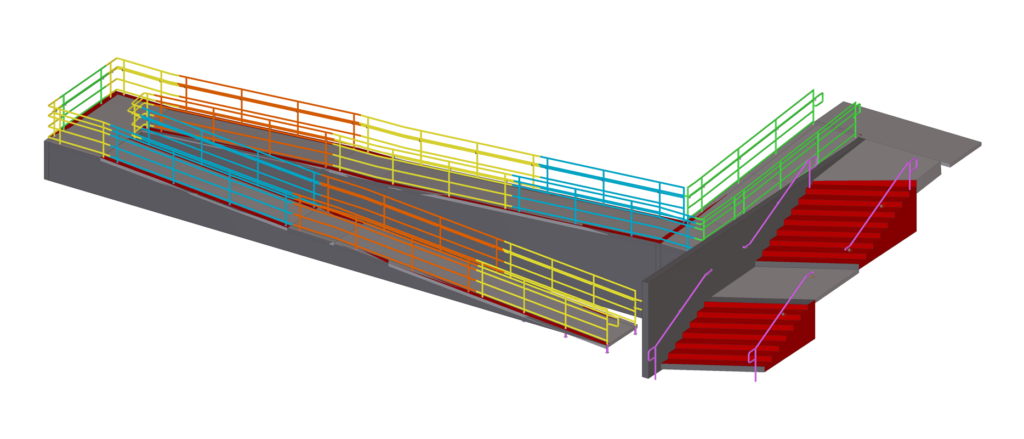

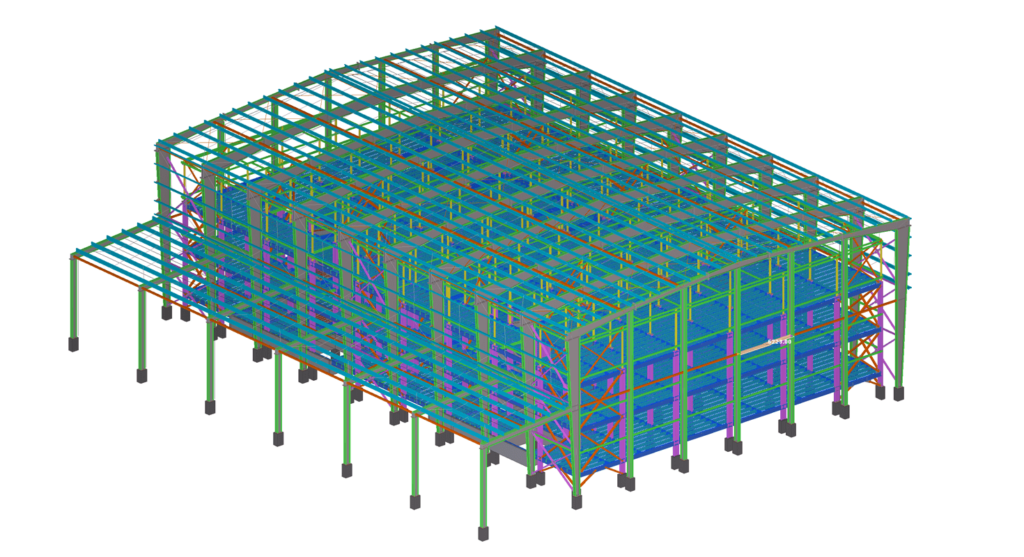

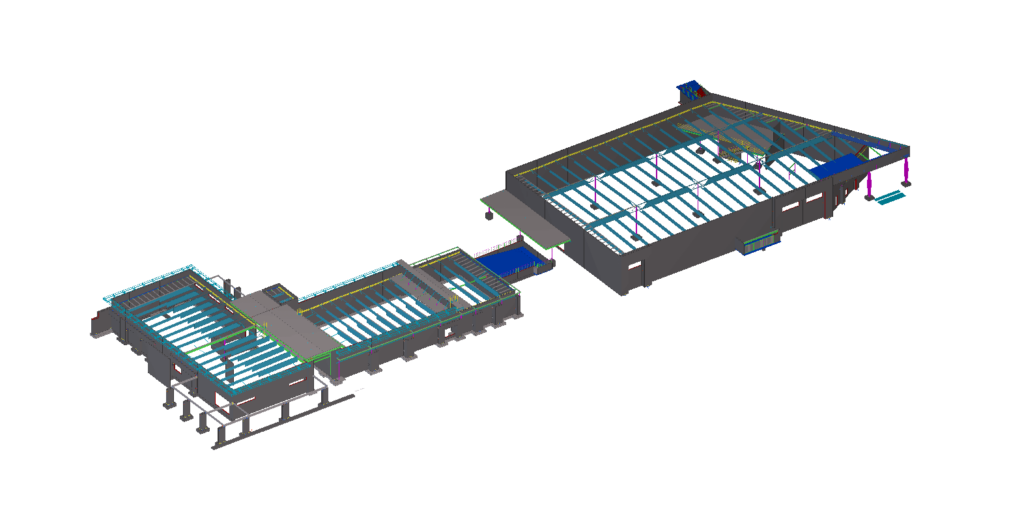

Arrow specializes at steel detailing. We have finished more than 500+ projects in the last six years. We detail the steel utilizing Tekla Structures. Any steel in your project can be detailed. Whether it’s an office building, a industrial structure, or a complicatedly twisted piece of metal, we’ll describe it. Each of our drawings is customized to the needs of your shop. Every type of electronic file is available to guarantee the efficient and effective functioning of your manufacturing. We are capable of handling inputs such as Architectural drawing, Structural drawing, Civil drawing & others, Navis works 3D, Auto Cad plan & 3D.

OUR RANGE OF DELIVERABLES INCULDES : Advance BOM, Anchor bolt plan, Embed plan, Shop drawing, E-plan and section, Deck layout , Filed bolt list, Stick model, 3Dpdf,IFC, files NC files, KSS files, EJE files, DXF files, BSWX Files, Deck layout.

Importance of Steel Detailing

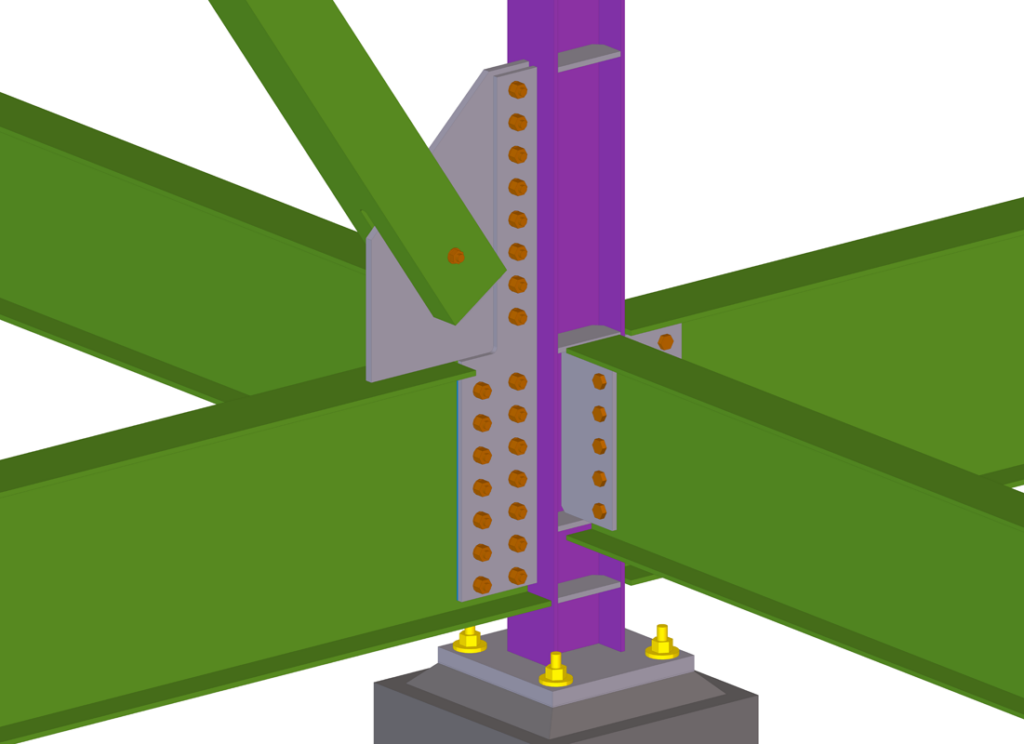

Accuracy and Precision

Steel detailing ensures that every steel component is accurately fabricated according to the design and specifications. This eliminates errors in the construction process and minimizes rework on-site.

Cost-Effective Fabrication

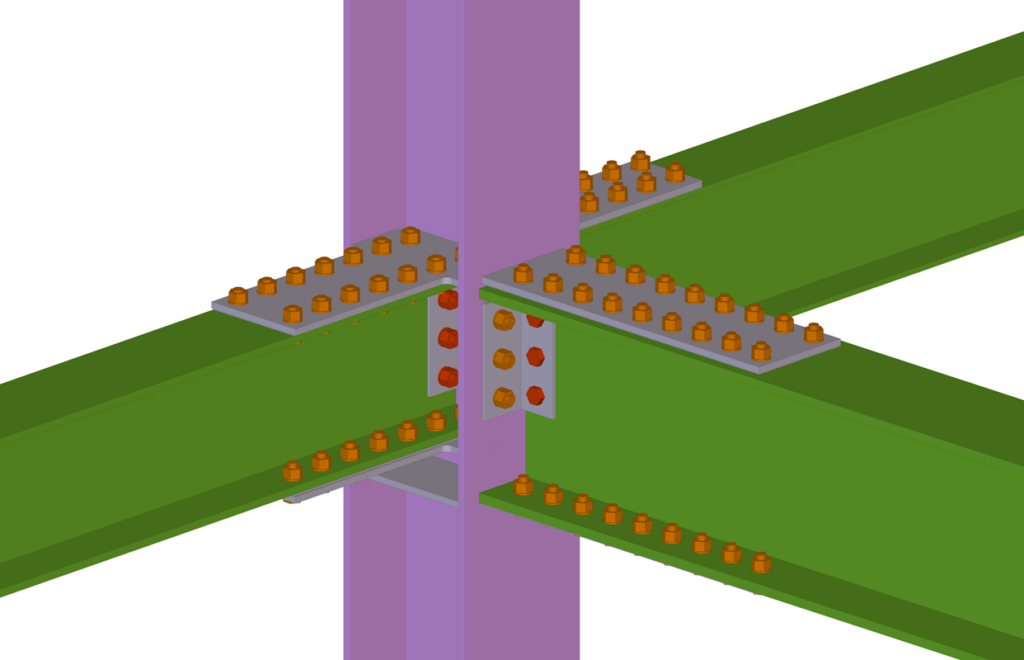

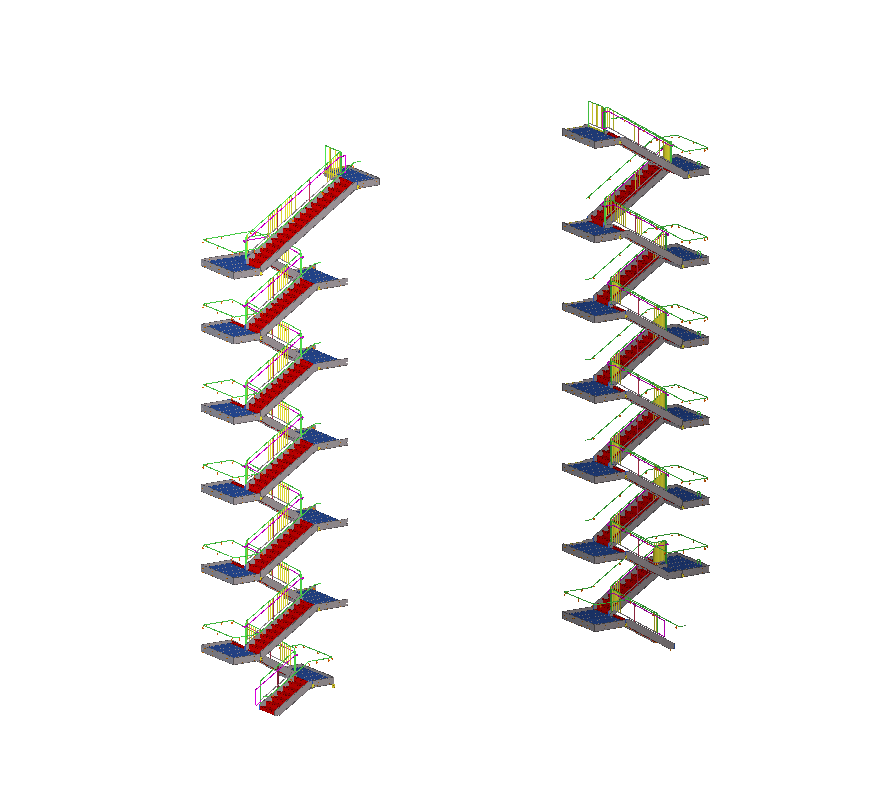

Detailed drawings help fabricators cut and shape steel components efficiently, reducing material waste and labor costs. It also ensures the components fit together correctly during the assembly.

Structural Integrity

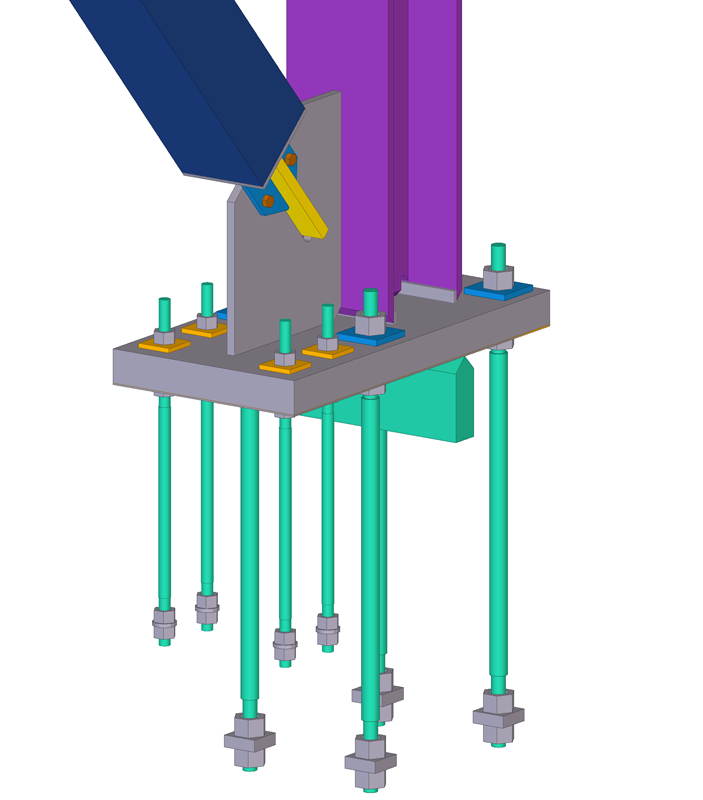

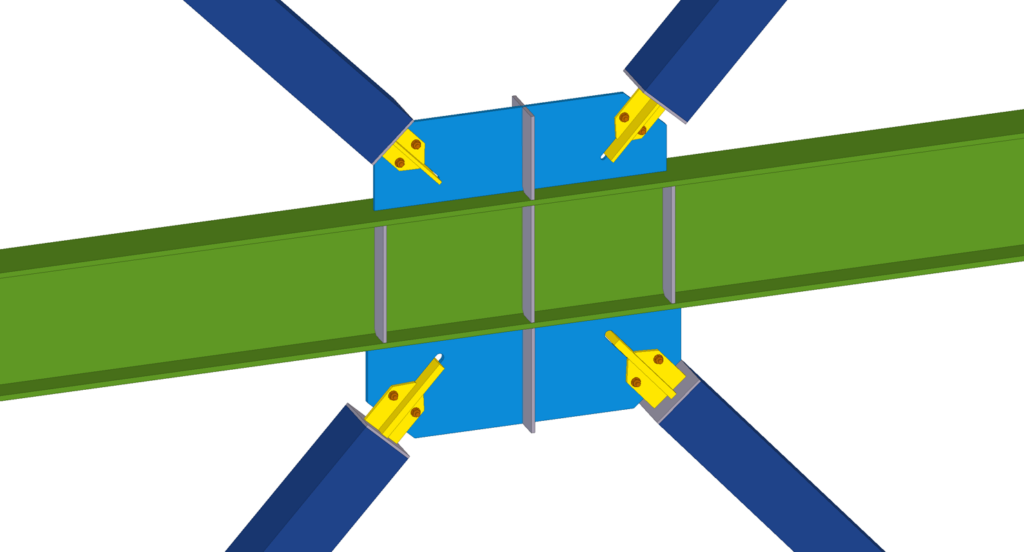

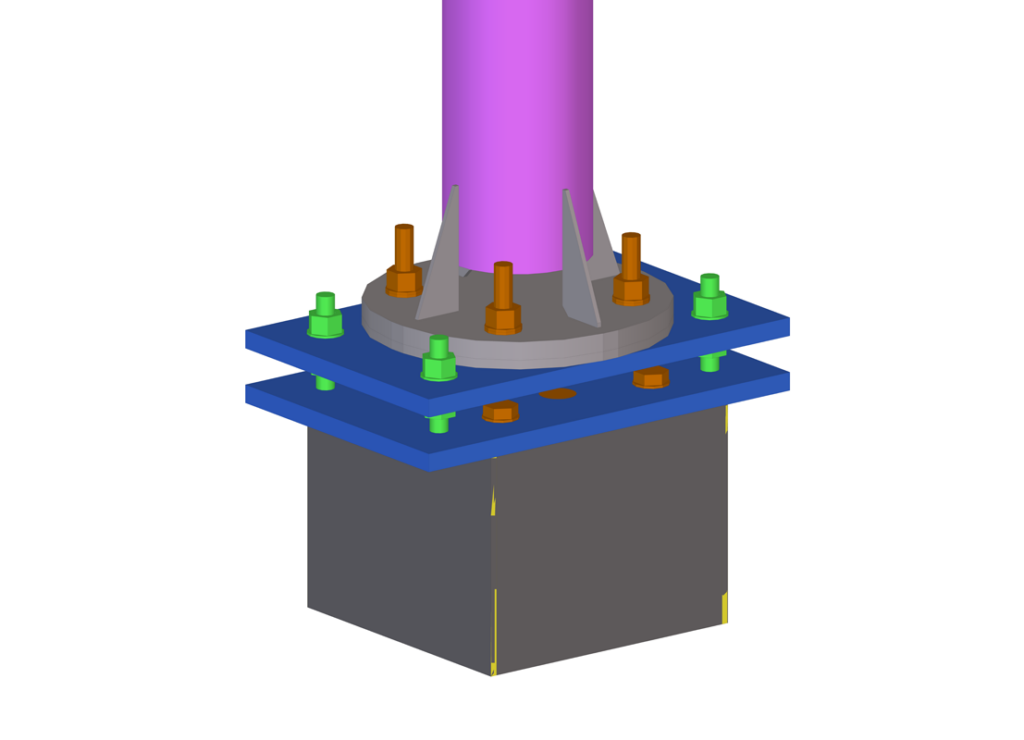

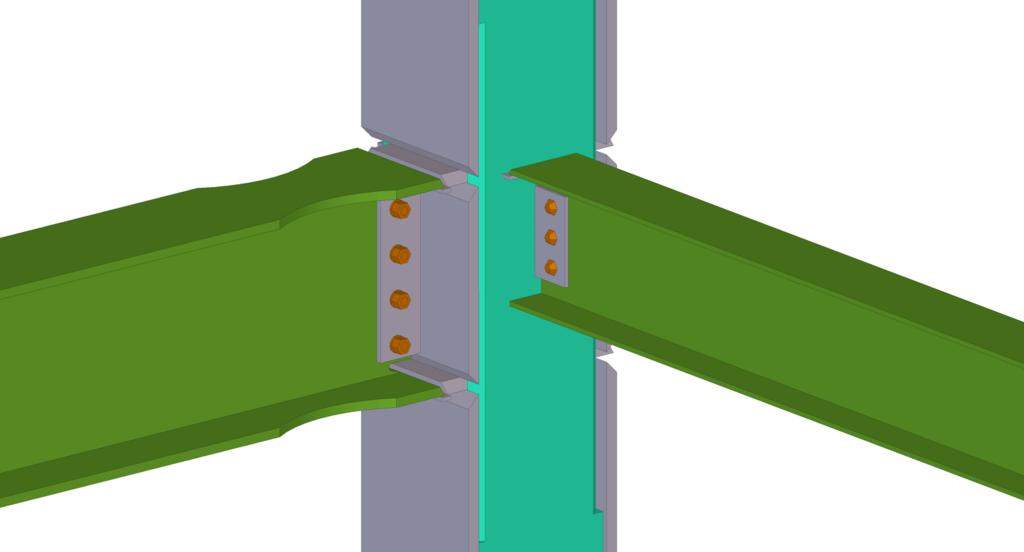

Proper detailing ensures the strength, stability, and safety of the structure. Correctly specified welds, bolts, and connections are critical to maintaining the integrity of the steel frame.

Facilitating Construction

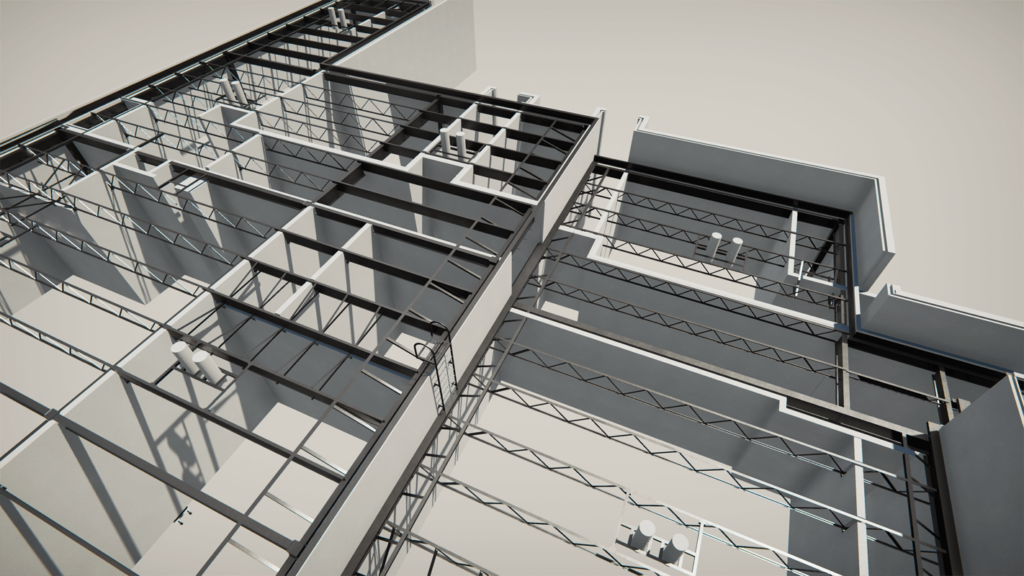

Detailed drawings and 3D models guide the construction team during erection, ensuring that steel components are installed in the correct sequence and with proper connections.

Clash Detection

3D models help detect any potential clashes between steel members and other elements like electrical conduits, HVAC systems, or plumbing. This reduces costly delays or design revisions during construction.

Compliance with Standards

Steel detailing ensures that all components meet industry standards and codes (e.g., AISC – American Institute of Steel Construction, BS – British Standards, NISD – National Institute of Steel Detailing in Compliance with Standards.), ensuring that the structure is safe and legal.